Reliable Workpiece Holding for Enhanced Machining Accuracy #

AUTOGRIP®’s stationary chucks are essential components in machining and industrial environments, designed to securely hold and grip workpieces during various operations. These chucks feature jaws that can be adjusted to tightly grip or release a workpiece, ensuring stability and precision throughout the machining process. Typically mounted on lathes or other machine tools, stationary chucks play a vital role in maintaining the correct position and orientation of workpieces, which is crucial for achieving consistent and accurate results.

Key Features and Installation Benefits #

AUTOGRIP® stationary chucks are engineered for straightforward installation and operational efficiency:

- Easy Mounting: The chuck can be quickly fixed onto the machine table, allowing for rapid replacement during setup.

- Integrated Hydraulic Cylinder: No separate installation is required, streamlining the setup process. Air pressure can also be used as an alternative power source.

- Flexible Piping Connection: The design enables simple connection of piping for hydraulic or pneumatic operation.

- Optional Vertical Chuck Seat Plate: For added versatility, a vertical chuck seat plate can be used as an option.

- Customization Available: AUTOGRIP® offers tailored solutions to meet specific requirements. Contact AUTOGRIP® for customized products.

Product Range and Series Overview #

AUTOGRIP® provides a diverse selection of stationary chucks to accommodate various machining needs:

- Combined Types:

- VH Series

- VP Series

- Integrated Types:

- SP Series

- SM Series

- SD Series

- SU Series

- SE Series

These chucks are suitable for use on drilling machines, milling machines, and cutting centers. Customers can select the most appropriate product based on their specific application requirements.

Selection Options #

To help users find the right stationary chuck, AUTOGRIP® offers a range of options:

- Machine Type: Machining Center

- Chuck Type: Long stroke, Pull back, Stationary Chuck, Thru-Hole, Non-Thru-Hole, Expansible, Pull Lock

- Chuck Size: 3", 4", 5", 6", 8", 10", 12", 16", 20", 24"

- Through Hole: Thru-Hole, Non-Thru-Hole

- Workpiece Shape: Round, Irregular, Flange type

- Requirement: Precision, 气密检知

- Gripping Type: Inner, Outer

- Number of Jaws: Two-Jaw, Three-Jaw

Advantages of AUTOGRIP® Stationary Chucks #

The primary function of a stationary chuck is to provide a stable and secure method for holding workpieces during machining operations such as drilling, milling, or grinding. AUTOGRIP® stationary chucks are designed to ensure:

- Consistent Positioning: Workpieces remain in the correct position and orientation, which is essential for accuracy.

- Versatility: Available in various sizes and configurations to suit different workpieces and machining tasks.

- Self-Centering Feature: Some models automatically center the workpiece as the jaws are tightened.

- Reversible Jaws: Certain chucks can grip both the inner and outer diameters of a workpiece.

AUTOGRIP® is dedicated to delivering quality, performance, and reliability. The engineering, manufacturing, and sales teams collaborate closely to develop solutions that address the diverse needs of customers.

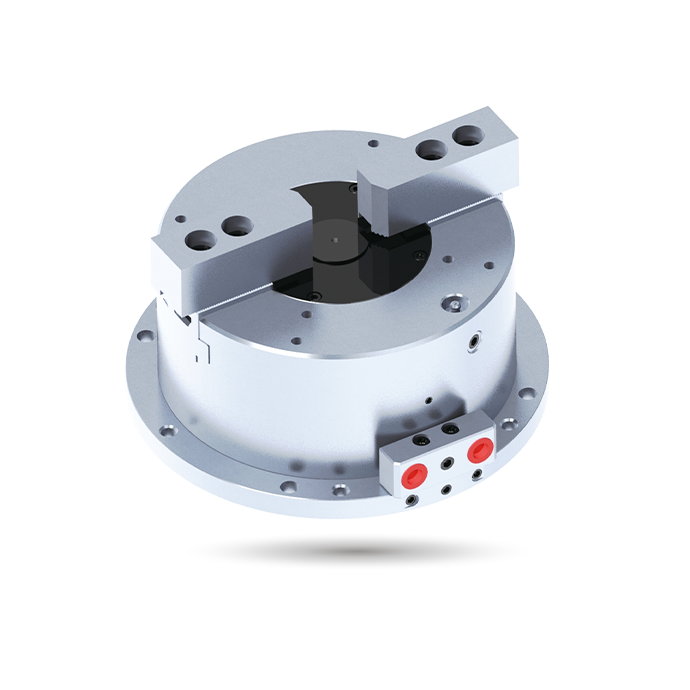

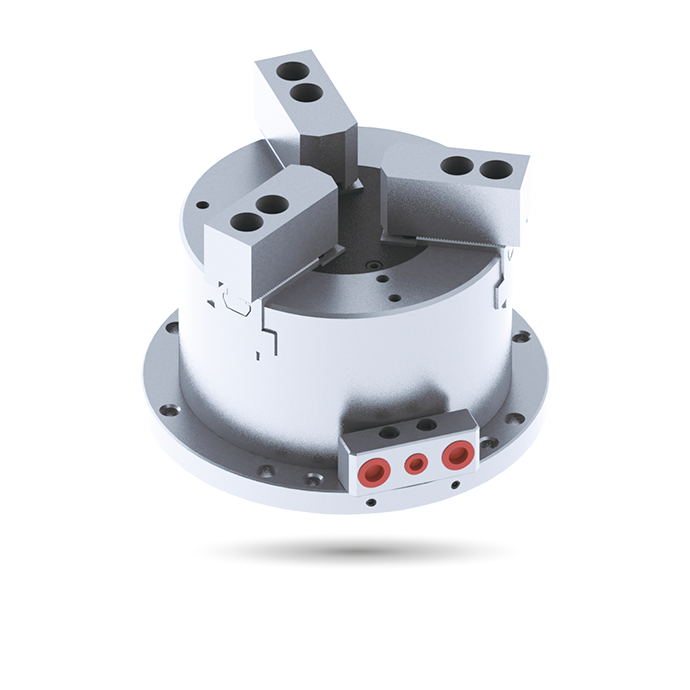

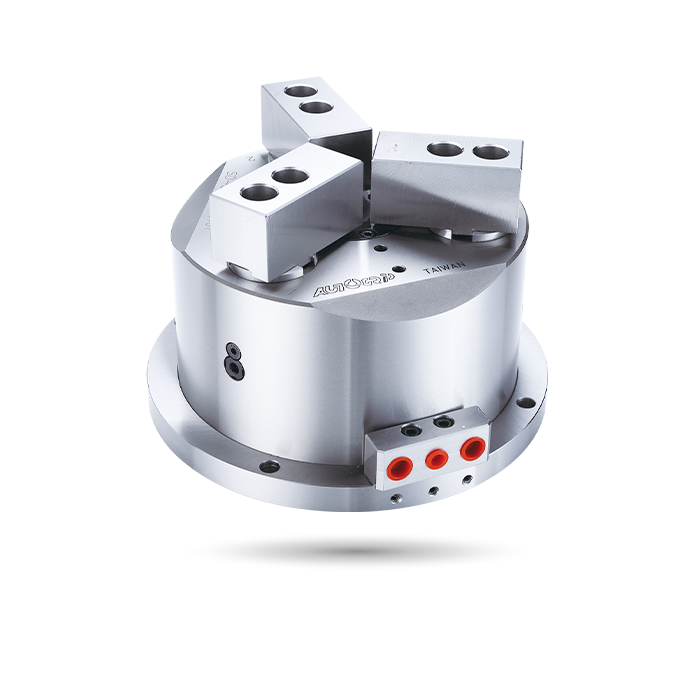

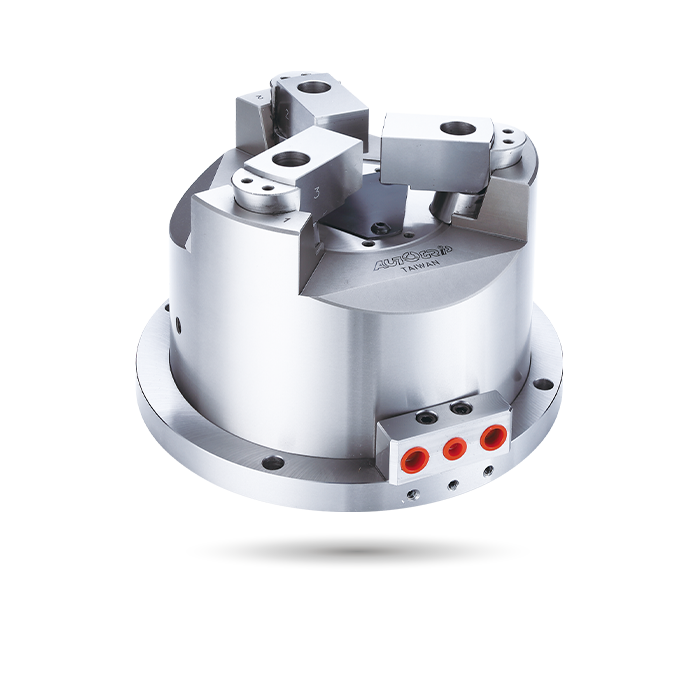

Product Gallery #

Ready to Enhance Your Machining Efficiency? #

With over 35 years of expertise, AUTOGRIP® delivers high-precision chucks and offers both custom solutions and ODM services. Reach out today!

VH

VH VP

VP SP-2

SP-2 SP-3

SP-3 SM

SM SD

SD SU

SU SE

SE MP4

MP4