Advanced Clamping Solutions for Unique Machining Challenges #

AUTOGRIP® offers a diverse selection of special purpose power chucks engineered to address the specific needs of complex workpieces and specialized machining operations. These chucks are meticulously designed to provide optimal stability and cutting efficiency, making them ideal for tasks such as milling and drilling where conventional clamping may fall short.

We recognize that every machining application presents its own set of challenges. Whether your process requires central water or gas injection, air tightness detection, or other custom functionalities, our team is committed to working closely with you to identify and deliver the most suitable chuck for your requirements.

Key Features and Customization Options #

- Designed for workpieces with unique shapes or special processing needs

- Enhanced stability and efficiency for demanding milling and drilling tasks

- Customizable with options such as central water/gas injection, air tightness detection, and more

- Wide selection to accommodate various machine types, chuck sizes, and workpiece geometries

Product Selection Guide #

Machine Type:

- Turning Center

Chuck Types Available:

- Finger Chuck

- Pull Back

- 2+2 Indexing

- Compensating Type

- Big Bore

- Thru-Hole

- Non-Thru-Hole

- Expansible

- Pull Lock

Chuck Sizes:

- 3" 4" 5" 6" 8" 10" 12" 15" 18" 21" 24" 32"

Through Hole Options:

- Thru-Hole

- Non-Thru-Hole

- Big Bore

Workpiece Types:

- Round

- Taper

- Irregular

- Large-size Shaft

- Pipe-type

- Flange Type

- Thin Workpiece

Requirements:

- Rough

- Precision

- Heavy Duty

- Air Tightness Detection

Gripping Types:

- Inner

- Outer

- Face Clamping

- With Center

Number of Jaws:

- Two-Jaw

- Three-Jaw

- Four-Jaw

Explore Our Special Purpose Power Chuck Models #

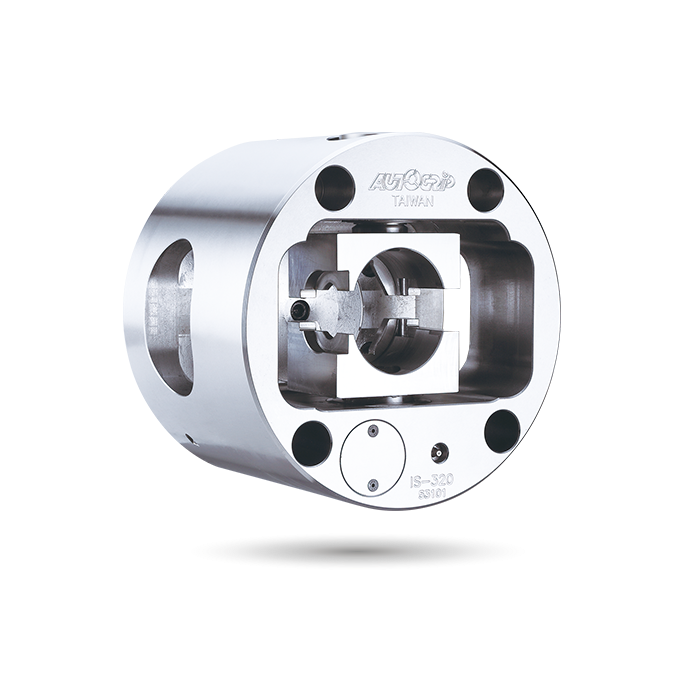

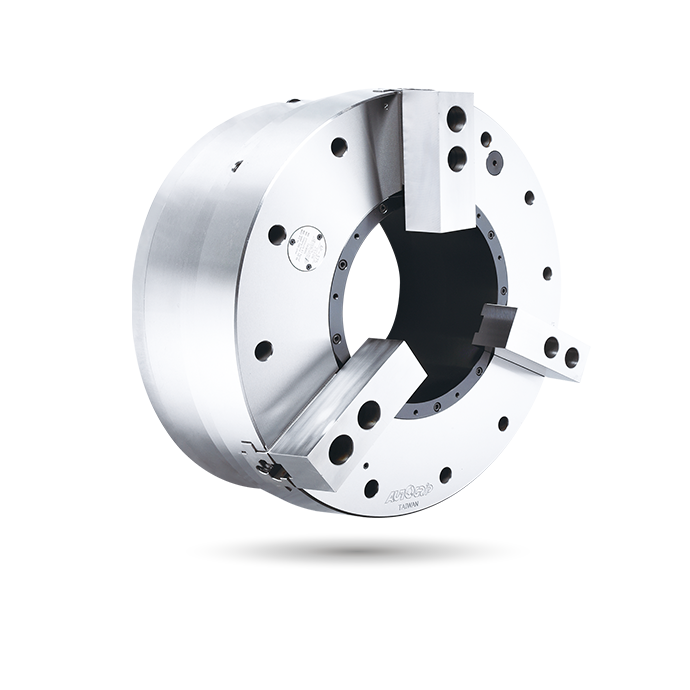

IS Power Indexing Chuck

IS Power Indexing Chuck

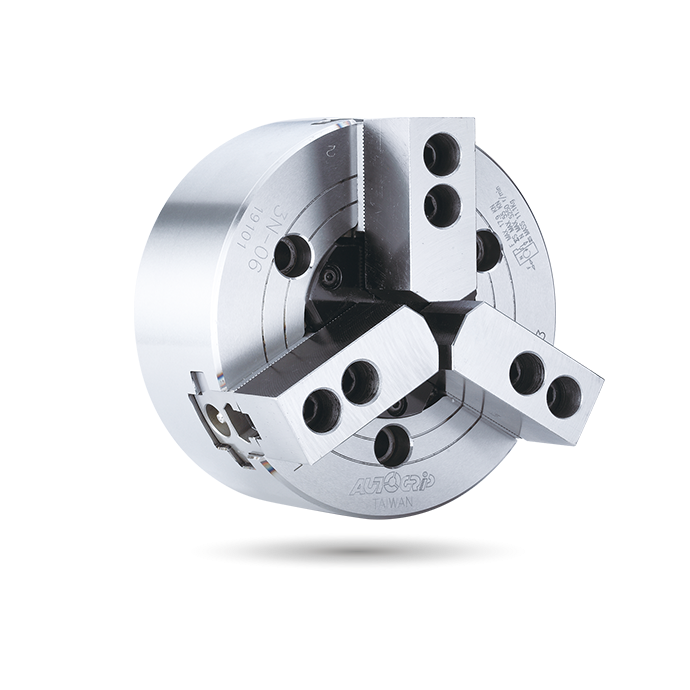

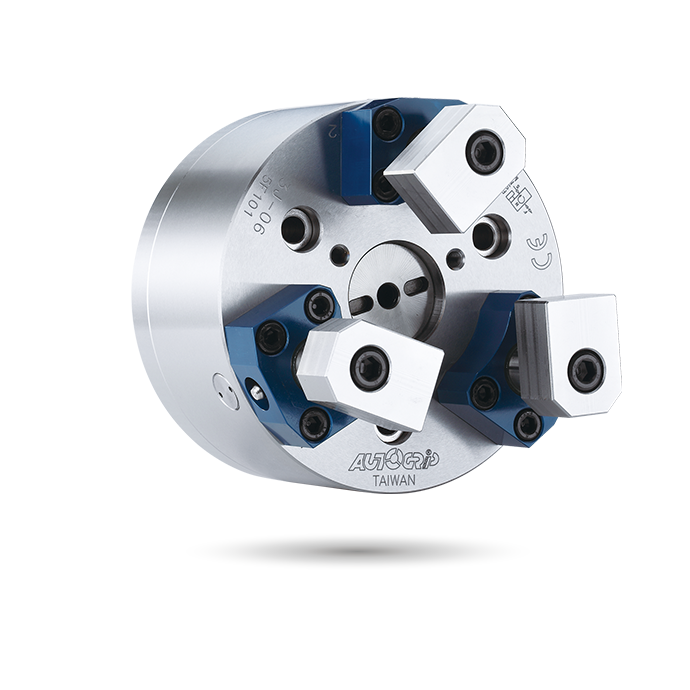

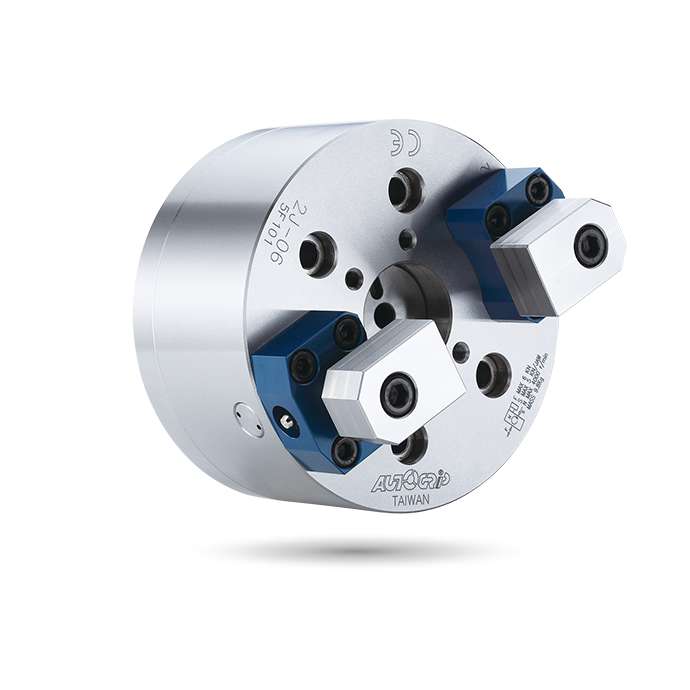

3N Non-Thru-Hole Chuck

3N Non-Thru-Hole Chuck

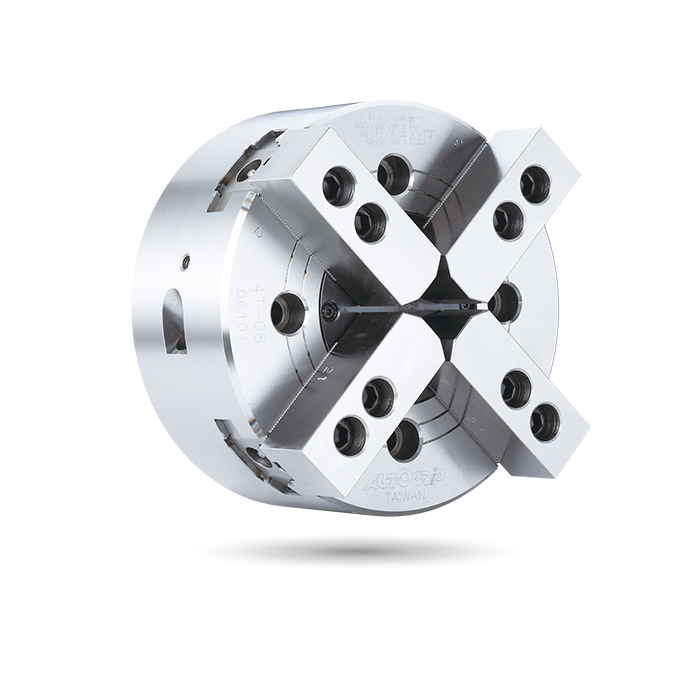

4T 4 Jaw Two Motion Type Independent Chuck

4T 4 Jaw Two Motion Type Independent Chuck

3D Pull Down 3-Jaw Chuck

3D Pull Down 3-Jaw Chuck

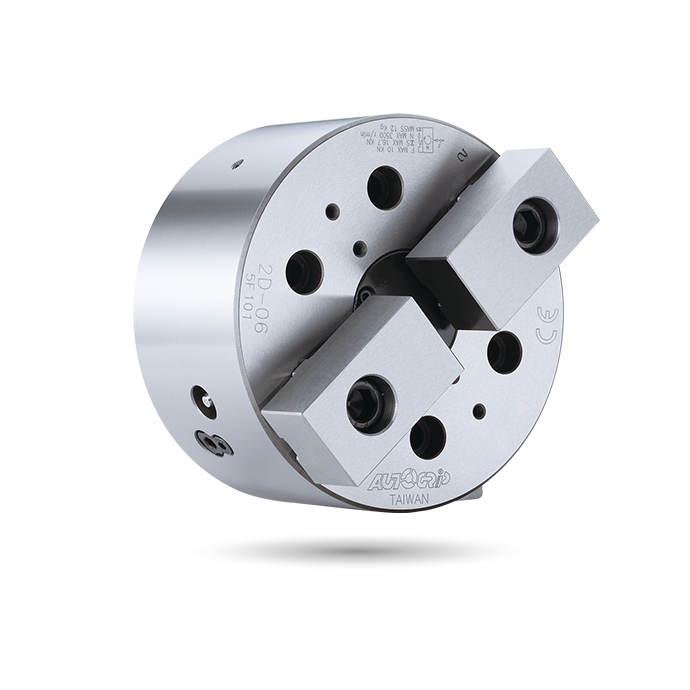

2D Pull Down 2-Jaw Chuck

2D Pull Down 2-Jaw Chuck

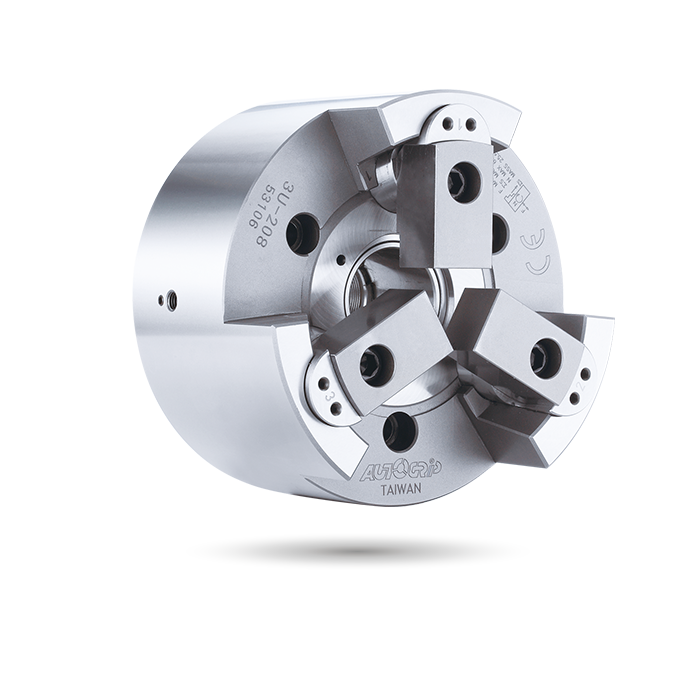

3U Pull Lock 3-Jaw Chuck

3U Pull Lock 3-Jaw Chuck

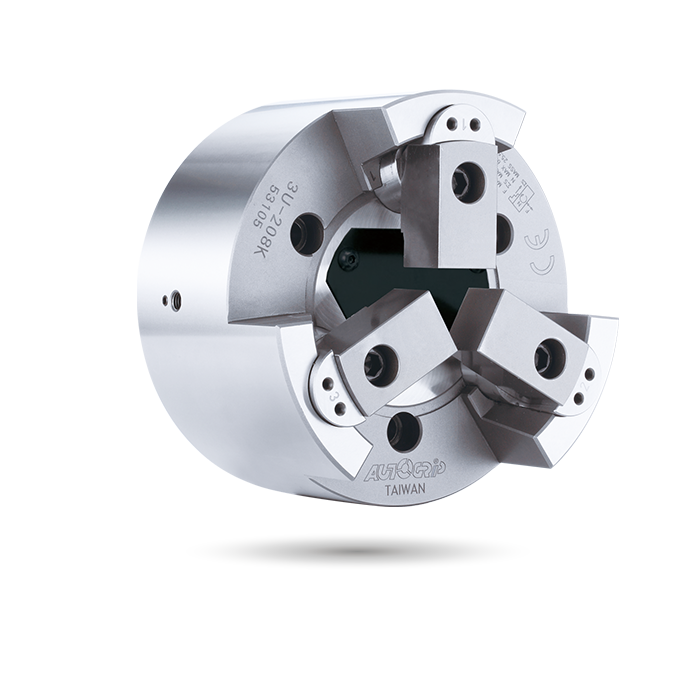

3U-K Non-Thru-Hole 3-Jaw Chuck

3U-K Non-Thru-Hole 3-Jaw Chuck

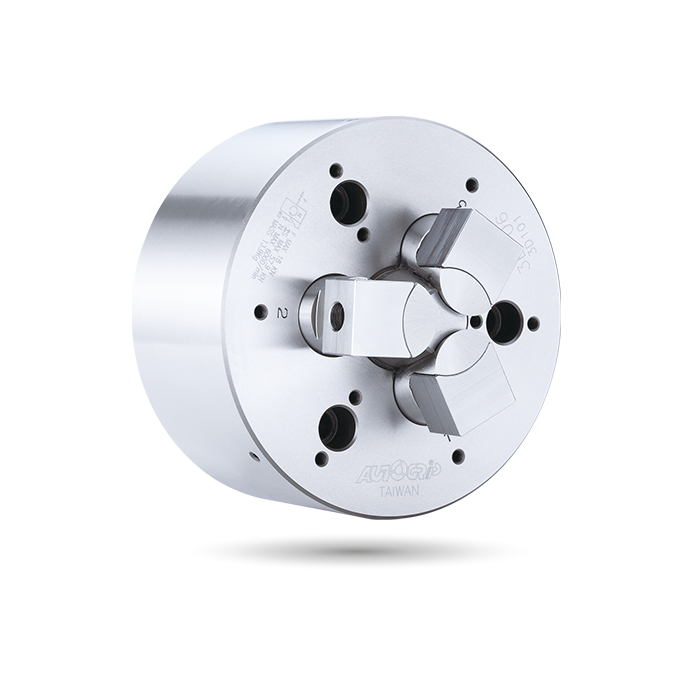

3E Non-Thru-Hole 3-Jaw Chuck

3E Non-Thru-Hole 3-Jaw Chuck

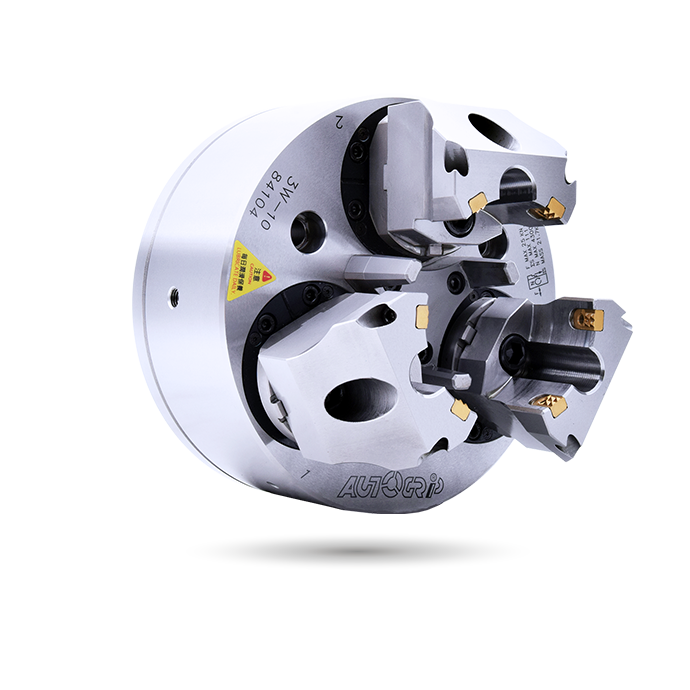

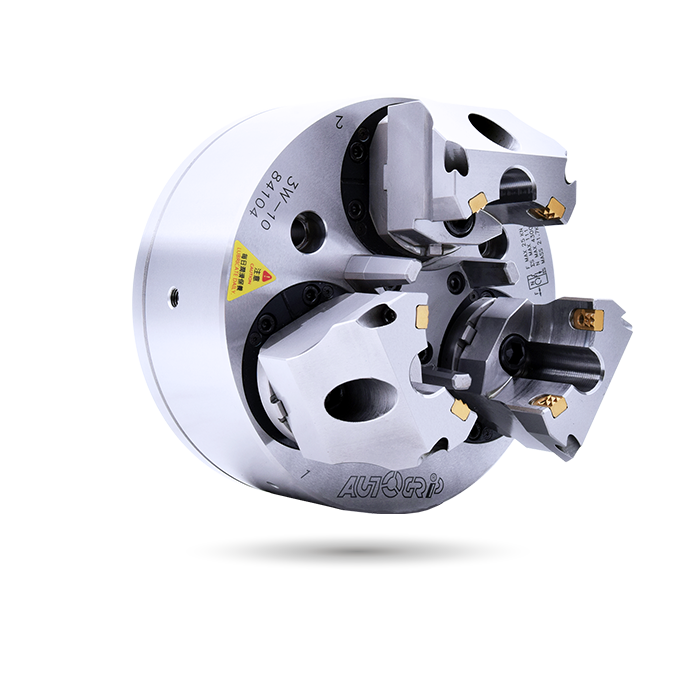

3W Swing Type 3-Jaw Chuck

3W Swing Type 3-Jaw Chuck

3W-C Swing Compensation-Type 3-Jaw Chuck

3W-C Swing Compensation-Type 3-Jaw Chuck

3RF Compensation-Type Retractable 3-Jaw Shaft Chuck

3RF Compensation-Type Retractable 3-Jaw Shaft Chuck

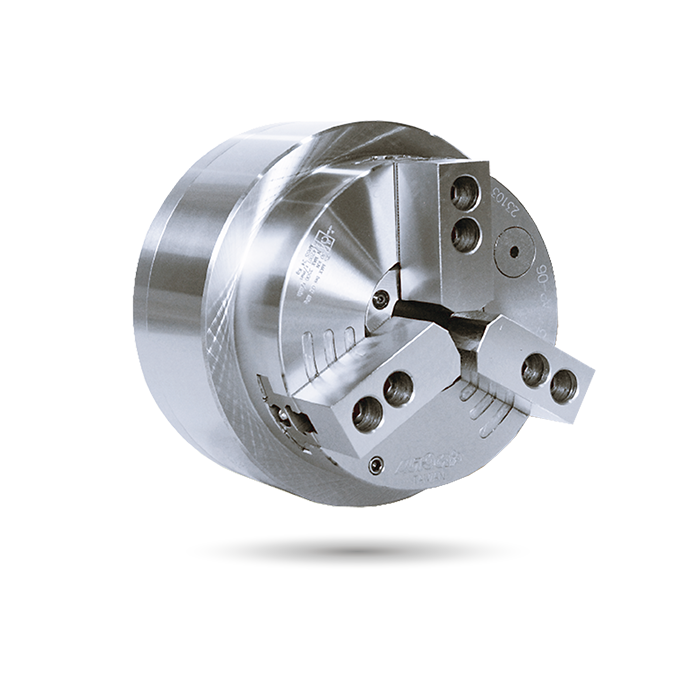

3R Compensation-Type 3-Jaw Power Chuck

3R Compensation-Type 3-Jaw Power Chuck

3J Non-Thru-Hole 3-Jaw Finger Power Chuck

3J Non-Thru-Hole 3-Jaw Finger Power Chuck

2J Non-Thru-Hole 2-Jaw Finger Power Chuck

2J Non-Thru-Hole 2-Jaw Finger Power Chuck

AP Thru-Hole 3-Jaw Air Chuck

AP Thru-Hole 3-Jaw Air Chuck

APS Thru-Hole 3-Jaw Air Chuck

APS Thru-Hole 3-Jaw Air Chuck

For further details or to discuss your specific clamping requirements, contact AUTOGRIP® for a tailored solution.