Comprehensive Guide to Rotary Hydraulic Cylinders for Automation #

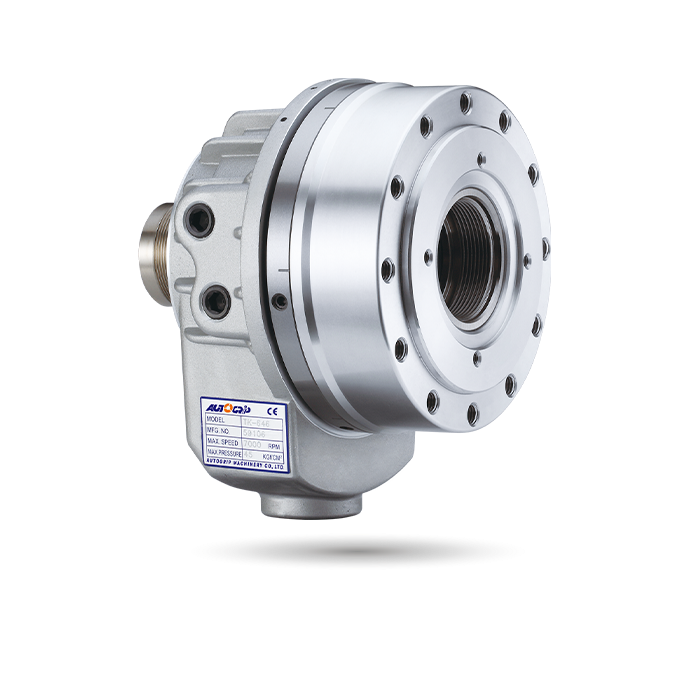

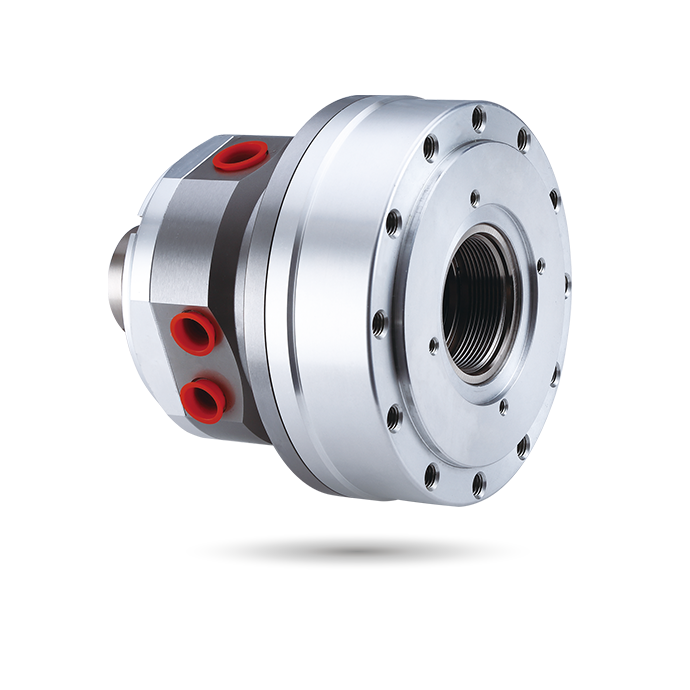

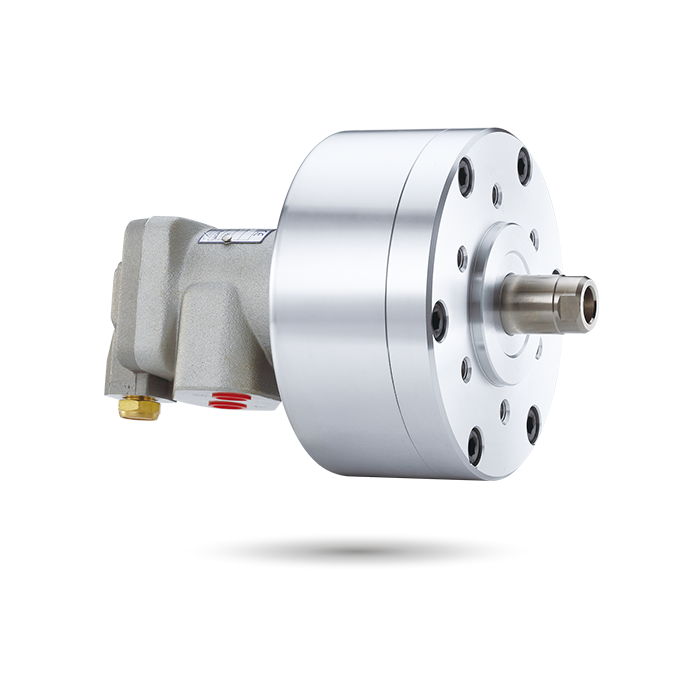

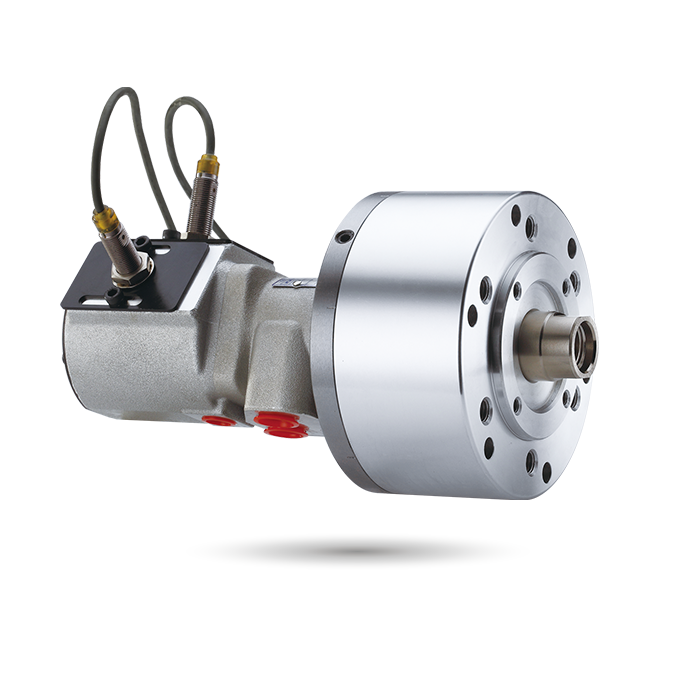

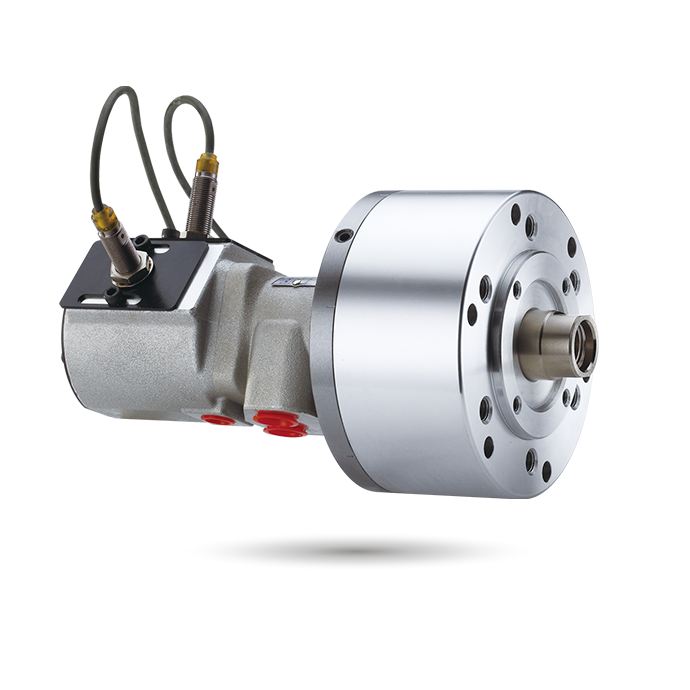

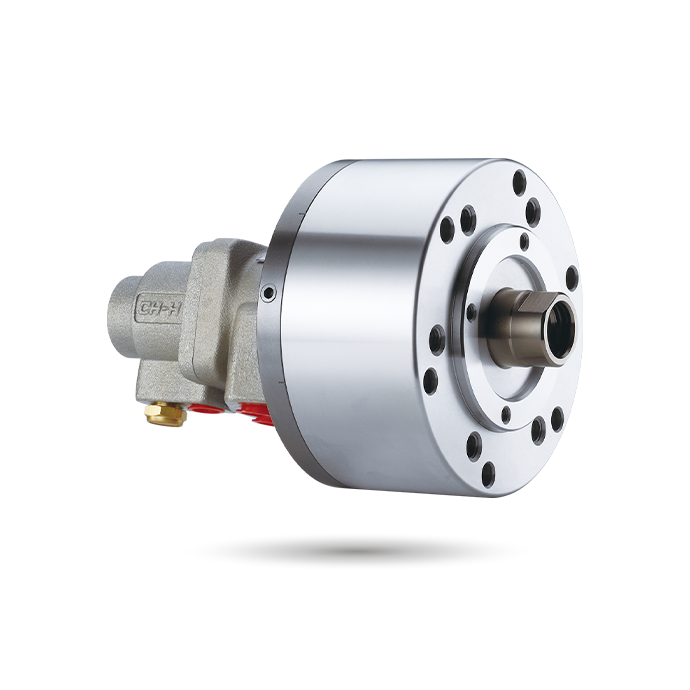

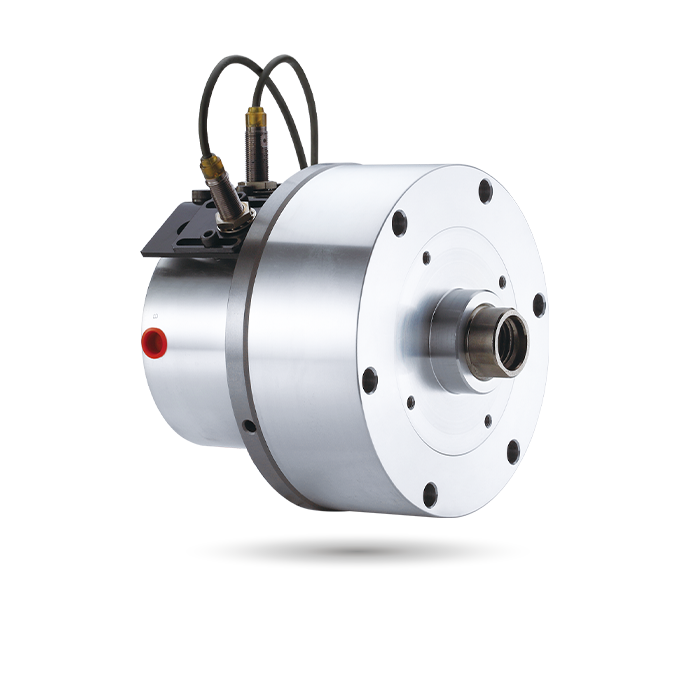

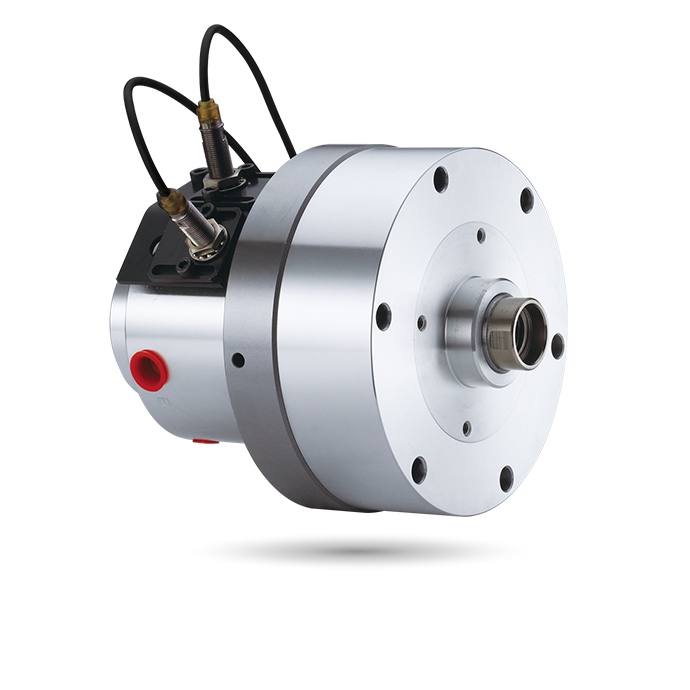

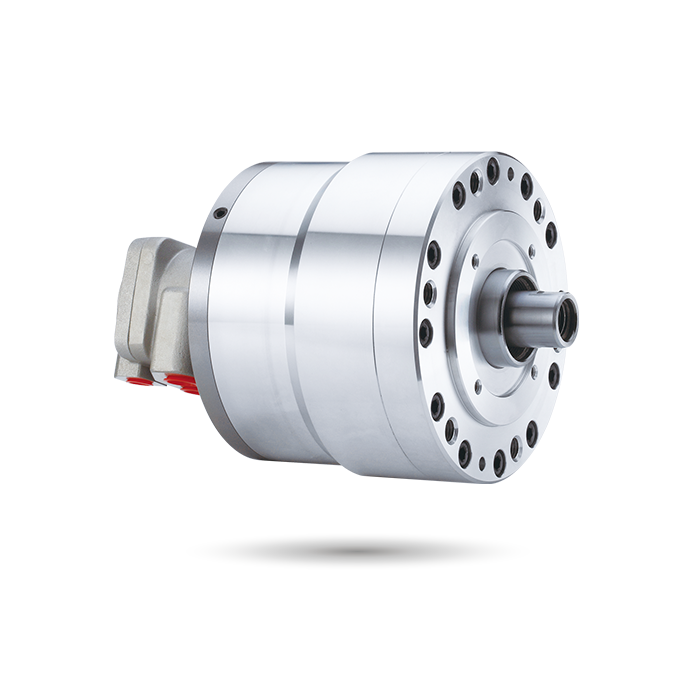

Looking to enhance your automation processes with reliable rotary cylinders? AUTOGRIP® offers a complete selection of rotating hydraulic cylinders engineered for high-speed spindle applications, ensuring efficient clamping and releasing of chucks in automated machining environments.

Overview of Rotary Cylinders #

Rotary cylinders are integral to automatic clamping systems, enabling precise and secure workpiece handling during machining. AUTOGRIP® provides two main types:

- Rotary hydraulic cylinders

- Rotary air cylinders

Hydraulic rotary cylinders from AUTOGRIP® feature a built-in non-return valve self-locking mechanism, supporting central air or water injection (depending on the model), and can be equipped with stroke detection mechanisms for accurate workpiece positioning.

Key Features of AUTOGRIP Rotary Hydraulic Cylinders #

- Built-in check valve with self-locking mechanism:

- Maintains secure clamping even if the pressure source fails or pipes are damaged, improving safety and operational efficiency.

- Pressure relief valve:

- Prevents overpressure, protecting the cylinder and extending equipment lifespan.

- Linear positioning sensing system:

- Enables full stroke detection with clamping positions set via Teach-in, eliminating manual adjustments. This enhances precision, reduces setup time, and boosts productivity.

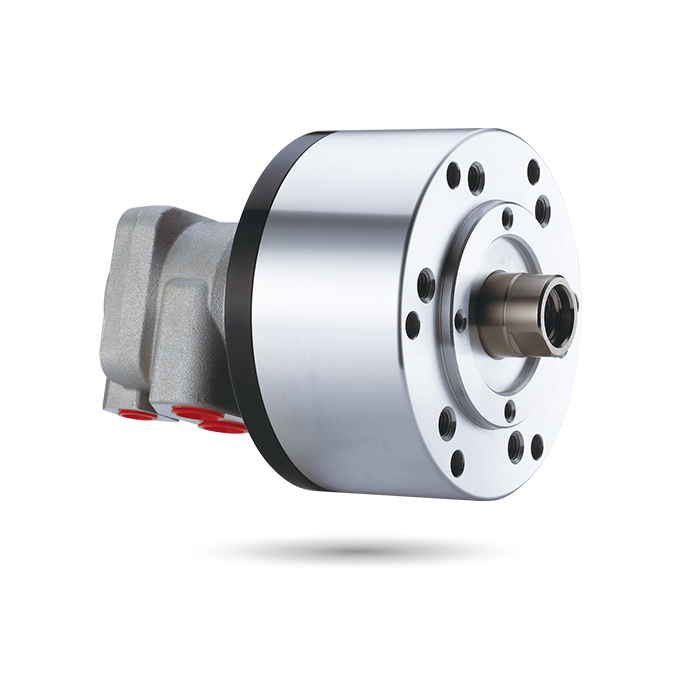

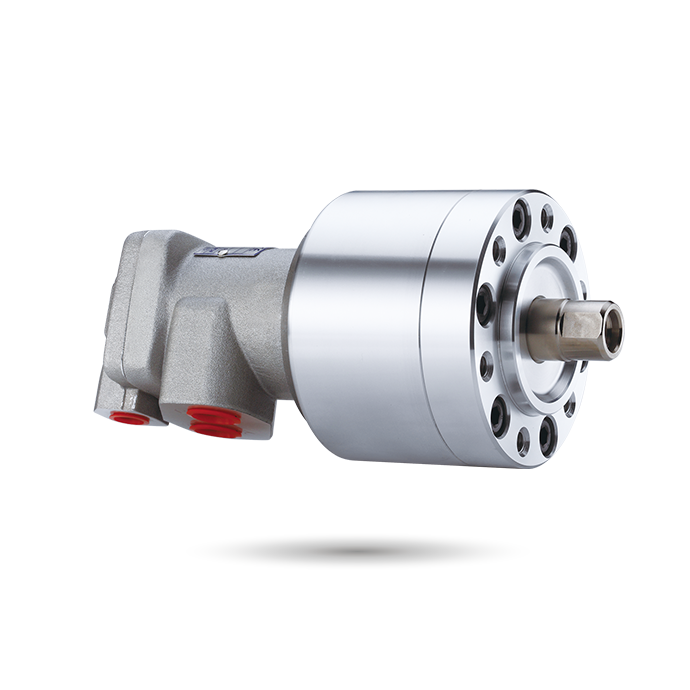

Main Components of a Rotary Hydraulic Cylinder Actuator #

- Cylinder Barrel: Contains hydraulic fluid and withstands internal pressure.

- Piston and Piston Rod: The piston moves inside the barrel, generating rotary motion, which is transmitted by the rod to external mechanisms.

- Seals: Prevent fluid leakage and maintain system pressure.

- End Caps: Seal the barrel ends and provide mounting points.

- Built-in Check Valve: Automatically locks to prevent sudden pressure drops if the source fails.

- Pressure Relief Valve: Controls internal pressure to avoid overpressure.

- Rotating Joint: Allows hydraulic fluid to flow during rotation.

- Linear Sensor (optional): Offers precise feedback by detecting piston stroke and holding positions.

Operation Principles #

- Hydraulic Energy Transmission: Hydraulic oil is pressurized and delivered into the cylinder.

- Piston Movement: The oil drives the piston, typically connected to a rack-and-pinion or screw mechanism.

- Conversion to Rotary Motion: Linear piston movement is converted to rotary motion.

- Rotary Output: The resulting rotary motion is used for clamping, releasing, or other rotational tasks.

Importance of Regular Maintenance #

Ensuring Optimal Performance #

- Operational efficiency: Routine cleaning and lubrication reduce friction, ensuring smooth operation.

- Failure prevention: Regular inspections and timely replacement of worn components help avoid unexpected breakdowns.

Extending Service Life #

- Minimized wear: Maintenance reduces friction-related damage, prolonging actuator life.

- Corrosion prevention: Cleaning prevents oil contamination and protects internal structures from corrosion.

Enhancing Safety #

- Accident prevention: Checking safety devices like check valves and pressure relief valves ensures they function correctly.

- Stability: Regular inspection of clamping and positioning systems prevents workpiece detachment or misalignment.

Basic Maintenance Steps #

- Hydraulic oil inspection and replacement: Regularly check oil quality and level; replace if aged or contaminated.

- Lubrication and cleaning: Lubricate moving parts and keep the cylinder surface clean.

- Seal inspection: Replace worn or aged seals to prevent leaks.

- Safety device testing: Periodically test check valves, pressure relief valves, and positioning systems.

- Maintenance record keeping: Document all maintenance activities for future reference and scheduling.

AUTOGRIP® Rotary Cylinder Product Lineup #

Explore our full range of rotary cylinders, designed to meet diverse automation needs. Below are some of the key models:

AUTOGRIP® is committed to delivering high-quality rotary cylinders tailored to the evolving needs of automation and machining industries. For partnership opportunities or to discuss your specific requirements, contact us.

TK

TK TS

TS TH

TH TR

TR RK

RK RK-N

RK-N RH

RH RA

RA RL

RL RS

RS RS-N

RS-N RL-N

RL-N RL-AN

RL-AN RC

RC RE

RE RE-A

RE-A RE-L

RE-L RD

RD