Power Chuck Solutions for Modern Manufacturing #

Autogrip®, established in Taiwan since 1989, has become a recognized name in power chuck manufacturing, collaborating with machine builders worldwide. The power chuck product line is engineered to offer flexibility, adaptability, and precision for a wide range of machining applications.

Product Range and Types #

Autogrip® provides a diverse selection of power chucks, each tailored to specific machining requirements:

- Thru-Hole Power Chucks: Hydraulic chucks ideal for round through-hole workpieces, ensuring high precision.

- Non-Thru-Hole Power Chucks: Designed for round adaptors, flange types, precision, and inner clamping, supporting diverse clamping needs.

- Large-Thru-Hole Power Chucks: Feature a larger through-hole than standard hollow chucks, compatible with industry-standard bore sizes for round workpieces.

- Long Jaw Stroke Power Chucks: Offer extended jaw travel for maximum clamping flexibility and robust performance, suitable for various industry needs.

- Vertical Lathe Power Chucks: Specialized for vertical lathe operations, these chucks provide excellent chip resistance and can be equipped with waterproof flanges for demanding environments.

- Fully Sealed Type Power Chucks: Designed for longevity with internal lubrication, reducing maintenance and supporting unmanned, dry, or high-pressure coolant machining operations.

Chucks are available in configurations with 1, 2, 3, 4, or 6 jaws, and can be customized to order. The V series accommodates workpieces up to 2,000mm (79") in diameter.

Key Features #

- High Torque and Rigidity: Rigid coupling transmits power efficiently at high speeds and torque.

- Quick Installation: Clamping devices allow for rapid workpiece changes, enhancing productivity.

- Adjustable Clamping Force: Adaptable to various workpiece materials and shapes, ensuring optimal machining conditions.

Advantages #

- Stability and Accuracy: High torque transmission and rigidity ensure workpiece stability and machining precision, even at elevated speeds.

- Even Clamping Force: Uniform force distribution enables high-precision machining and improved efficiency.

- Versatility: Suitable for a wide range of workpiece shapes and sizes, making them applicable across multiple industries.

Applications #

Autogrip® power chucks are utilized in:

- Metalworking: On lathes, milling, drilling, and grinding machines for clamping and torque transmission.

- Robotics: At robotic joints for high-precision, high-torque movements.

- Precision Machining: For manufacturing optical, electronic, and precision mechanical components.

Product Gallery #

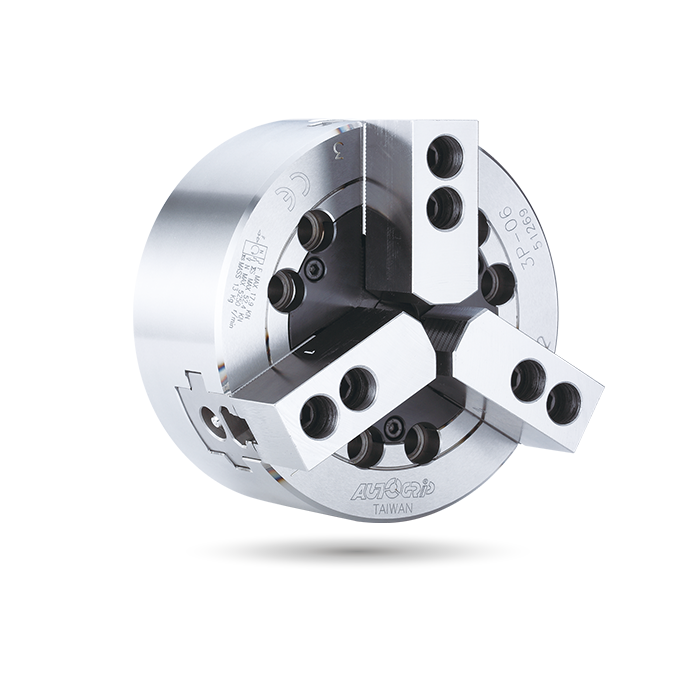

3H/3H-A Thru-Hole 3-Jaw Power Chuck

3H/3H-A Thru-Hole 3-Jaw Power Chuck

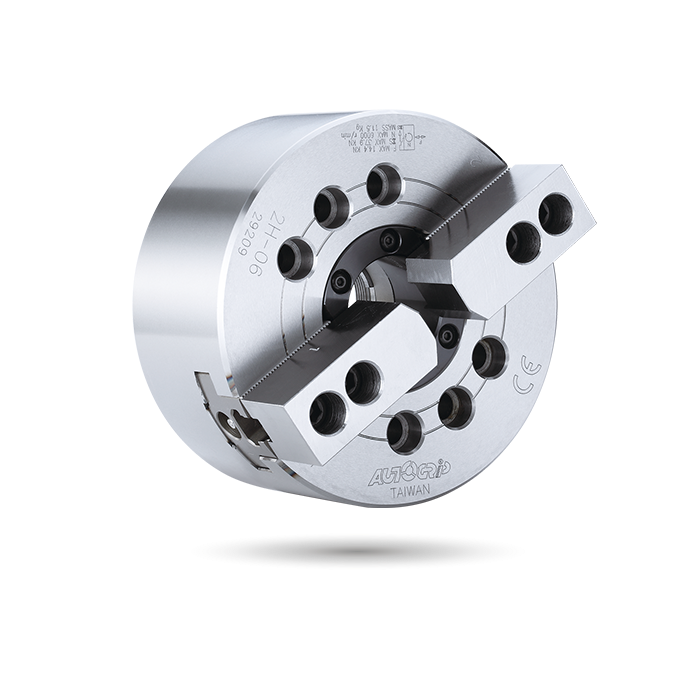

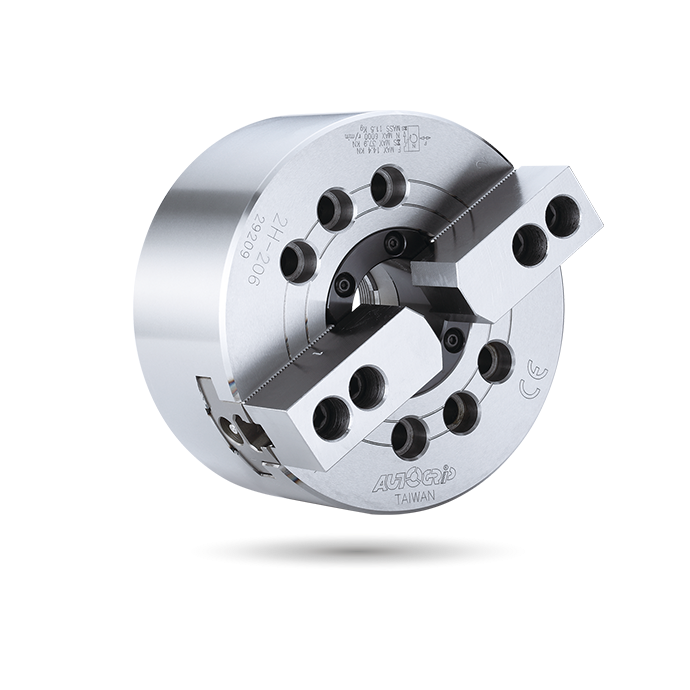

2H/2H-A Thru-Hole 2-Jaw Power Chuck

2H/2H-A Thru-Hole 2-Jaw Power Chuck

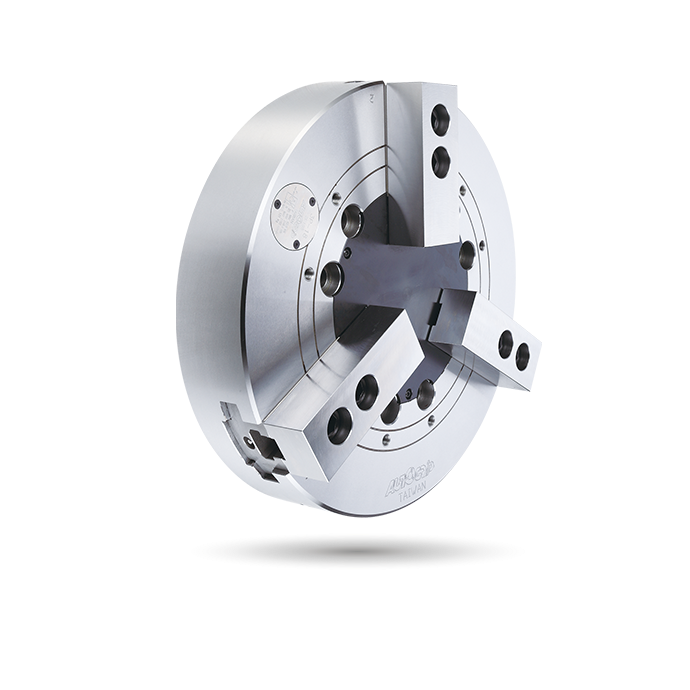

4H/4H-A Thru-Hole 4-Jaw Lathe Chuck

4H/4H-A Thru-Hole 4-Jaw Lathe Chuck

2H-2/2H-2A Large Thru-Hole 2-Jaw Power Chuck

2H-2/2H-2A Large Thru-Hole 2-Jaw Power Chuck

4H-2/4H-2A Large Thru-Hole 4-Jaw Power Chuck

4H-2/4H-2A Large Thru-Hole 4-Jaw Power Chuck

3H-2/3H-2A Large Thru-Hole 3-Jaw Power Chuck

3H-2/3H-2A Large Thru-Hole 3-Jaw Power Chuck

3P-2/3P-2A Non-Thru-Hole 3-Jaw Power Chuck

3P-2/3P-2A Non-Thru-Hole 3-Jaw Power Chuck

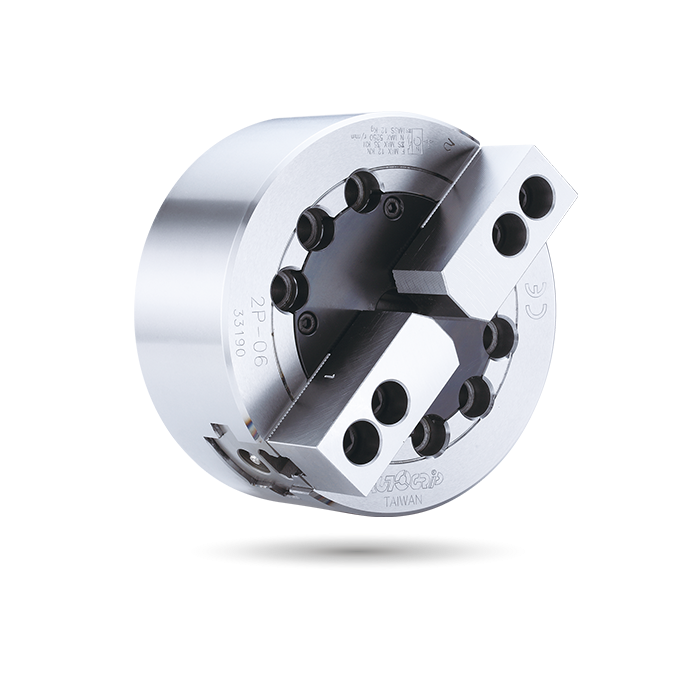

2P/2P-A Non-Thru-Hole 2-Jaw Power Chuck

2P/2P-A Non-Thru-Hole 2-Jaw Power Chuck

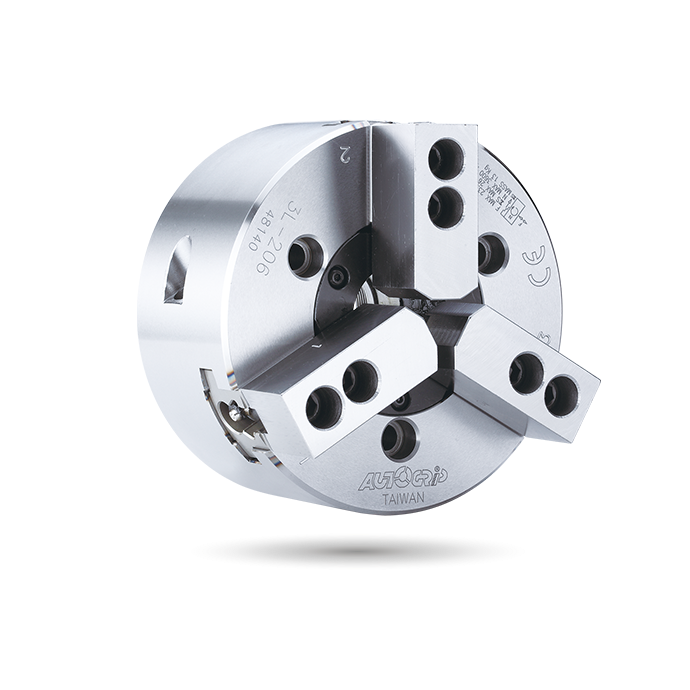

3L/3L-A Extra Long Stroke Thru-Hole 3-Jaw Power Chuck

3L/3L-A Extra Long Stroke Thru-Hole 3-Jaw Power Chuck

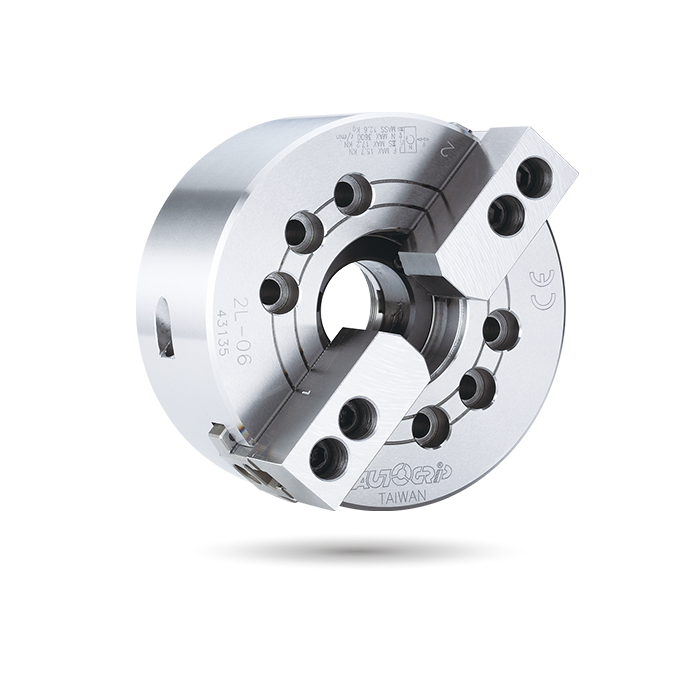

2L/2L-A Extra Long Stroke Thru-Hole 2-Jaw Power Chuck

2L/2L-A Extra Long Stroke Thru-Hole 2-Jaw Power Chuck

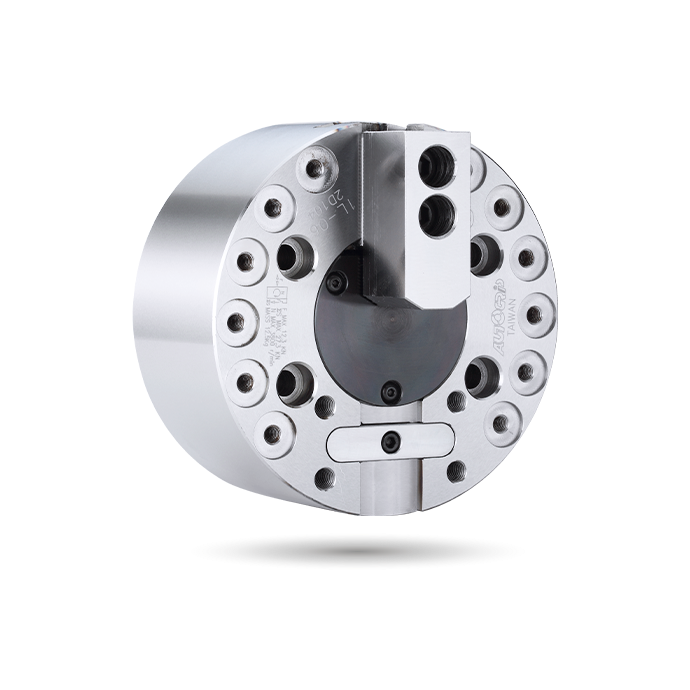

1L/1L-A Extra Long Jaw Stroke Power Chuck

1L/1L-A Extra Long Jaw Stroke Power Chuck

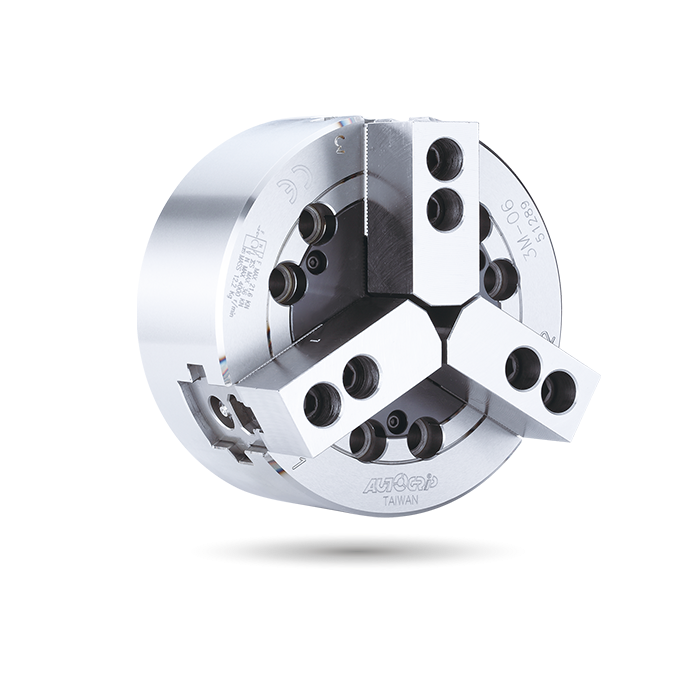

3M Non-Thru-Hole Long Jaw Stroke 3-Jaw Power Chuck

3M Non-Thru-Hole Long Jaw Stroke 3-Jaw Power Chuck

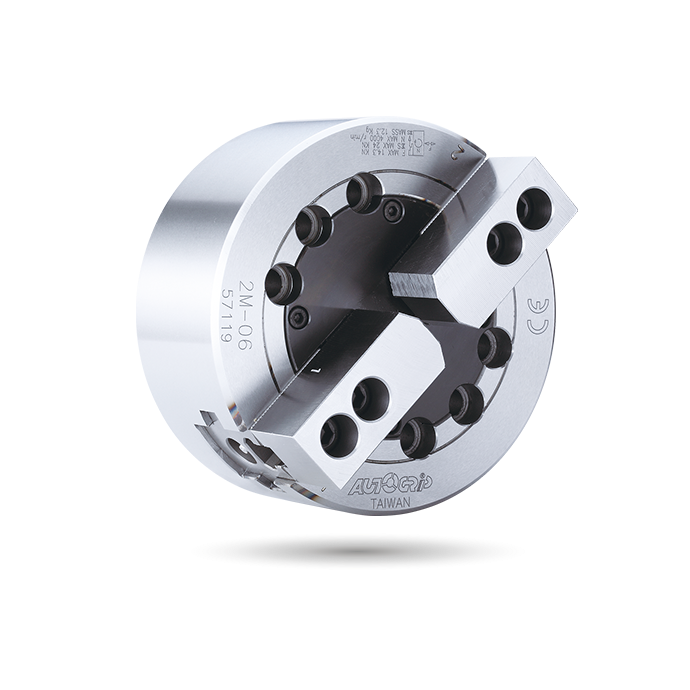

2M Non-Thru-Hole Long Stroke 2-Jaw Lathe Chuck

2M Non-Thru-Hole Long Stroke 2-Jaw Lathe Chuck

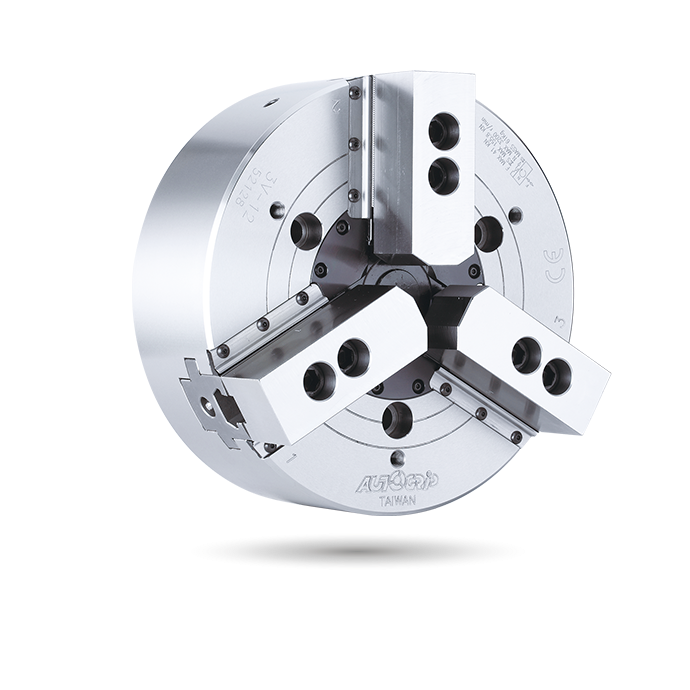

3V/3V-A Power Chuck for Vertical Lathe

3V/3V-A Power Chuck for Vertical Lathe

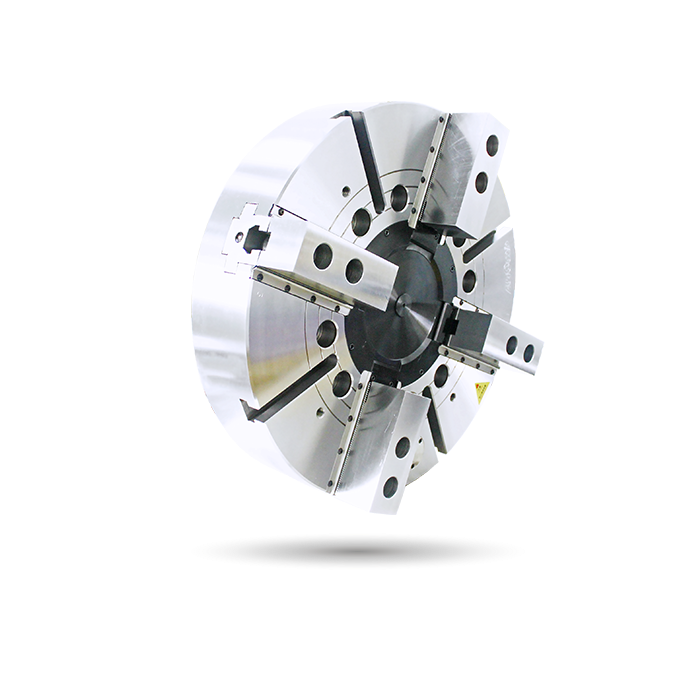

4V/4V-A Power Chuck for Vertical Lathe

4V/4V-A Power Chuck for Vertical Lathe

3HS Fully Sealed Thru-Hole 3-Jaw Power Chuck

3HS Fully Sealed Thru-Hole 3-Jaw Power Chuck

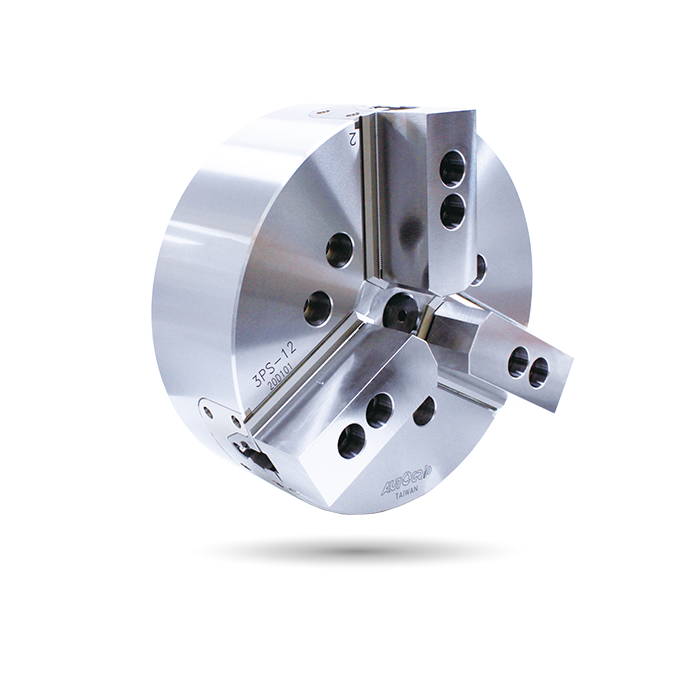

3PS Fully Sealed Non-Thru-Hole 3-Jaw Power Chuck

3PS Fully Sealed Non-Thru-Hole 3-Jaw Power Chuck

3P/3P-A Non-Thru-Hole Power Chuck

3P/3P-A Non-Thru-Hole Power Chuck

Commitment to Innovation #

Autogrip®’s R&D department is dedicated to ongoing product development, ensuring their power chucks meet the evolving demands of global manufacturing.

For more information or to discuss custom solutions, contact Autogrip®.