Precision Workholding Solutions for Modern Machining #

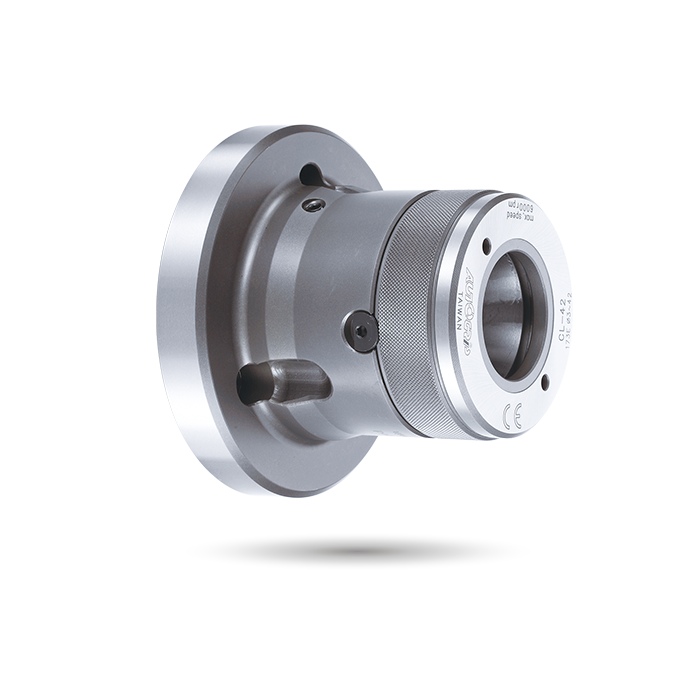

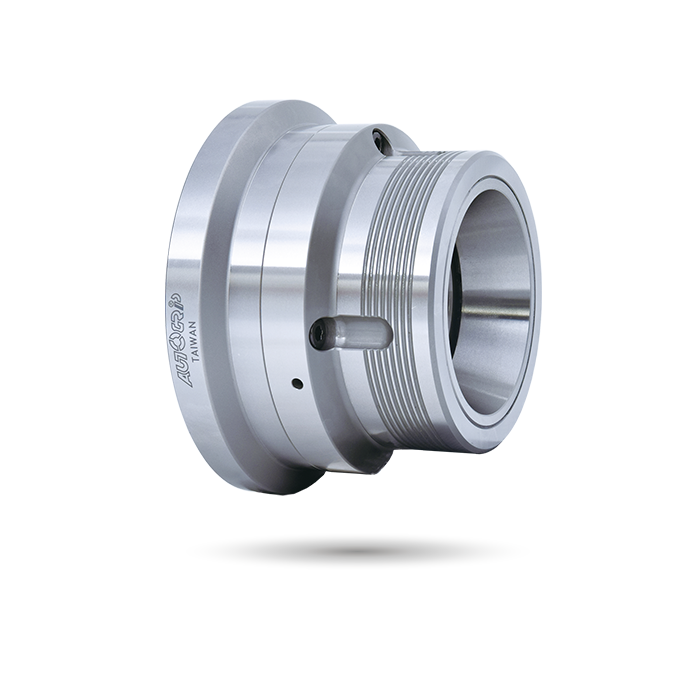

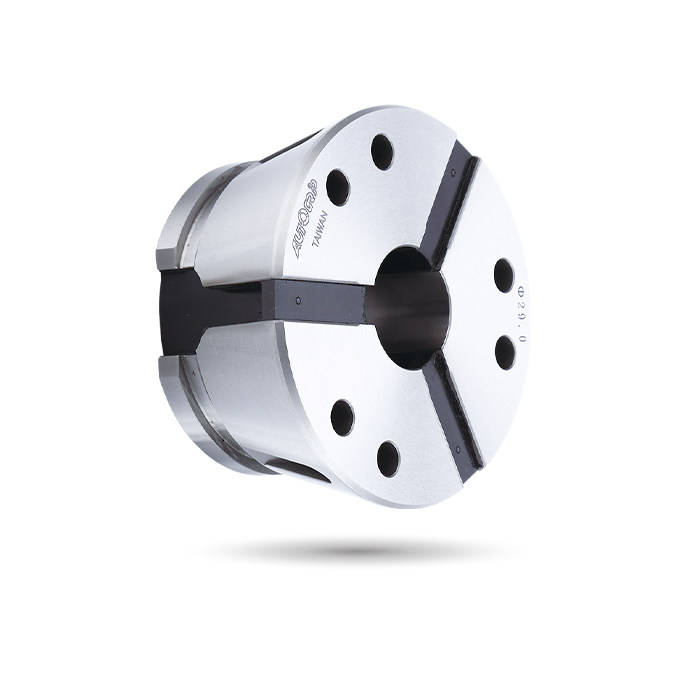

AUTOGRIP® is recognized as a leading manufacturer of collet chucks in Taiwan, offering solutions engineered for superior clamping force and higher operational speeds compared to conventional collet chucks. The unique mechanism operates by moving the inner collet bushing, altering the taper and actuating the inner elastic collet to securely clamp the workpiece. This design results in a compact profile, minimizing tool interference and making these chucks ideal for small work holding or automatic bar feeding from the rear.

A standout feature of AUTOGRIP® collet chucks is the proprietary waterproof design, which effectively prevents cutting fluid from entering the spindle’s through hole. This innovation extends the lifespan of the chuck, ensuring reliability in demanding machining environments.

Key Benefits and Applications #

- Enhanced Clamping: The all-around clamping mechanism distributes force evenly across the workpiece circumference, reducing deformation and ensuring stability.

- Efficient Changeovers: Quick jaw change and anti-swarf features minimize downtime, improving productivity. The system is compatible with robotic arms for automated line changes.

- Protection Against Wear: A rubber layer blocks chips from entering the chuck, significantly reducing wear and the risk of jamming.

AUTOGRIP® offers a comprehensive range of CNC lathe collet chucks, including draw types, end-stop types, and dead-length types. Available collet types include spring collets and rubber grip collets. For custom requirements, tailored solutions are available upon request.

When to Choose a Collet Chuck Over a Three-Jaw Chuck? #

- Small Workpieces: Rubber grip collets are especially effective for small diameter workpieces, providing consistent and concentric clamping that outperforms three-jaw chucks in these scenarios.

- Precision Needs: Known for their accuracy and repeatability, rubber grip collets are preferred for operations demanding tight tolerances and high precision. The uniform clamping force ensures reliable results.

- Improved Machining Access: The compact design of collet chucks reduces tool interference, offering better access to the workpiece and enhancing machining efficiency, particularly in complex or confined geometries.

- Rapid Changeovers: Operators can quickly switch between different workpieces by changing collets, eliminating the need for individual jaw adjustments and supporting agile production environments.

- High-Speed Operations: Collet chucks are capable of handling higher RPMs than three-jaw chucks, making them suitable for high-speed machining and the production of intricate small parts.

- Round Bar Feeding: Commonly used for round workpieces, collet chucks securely hold long bars, ensuring stability during continuous processing.

- Axial Runout Control: Rubber grip collets excel at minimizing axial runout, which is vital for maintaining concentricity in precision machining tasks.

Workpiece vs. Tool Collet Chucks #

A collet chuck can be designed for either workpiece or tool holding. AUTOGRIP® collet chucks are specifically optimized for workpiece clamping and are not intended for tool holding. Workpiece collet chucks feature a larger gripping range to accommodate various sizes and shapes, and are constructed to withstand the forces of machining. They are commonly used in milling machines, lathes, and other machining equipment, providing a strong, precise grip necessary for reliable operation.

Product Range #

Features at a Glance #

- Even distribution of clamping force to minimize workpiece deformation

- Quick jaw change and anti-swarf design for reduced downtime

- Compatibility with robotic automation for production lines

- Rubber protection layer to prevent chip ingress and reduce wear

AUTOGRIP® continues to support machining professionals with high-quality, reliable collet chuck solutions. For tailored requirements or further information, contact AUTOGRIP®.

CL

CL CL-A

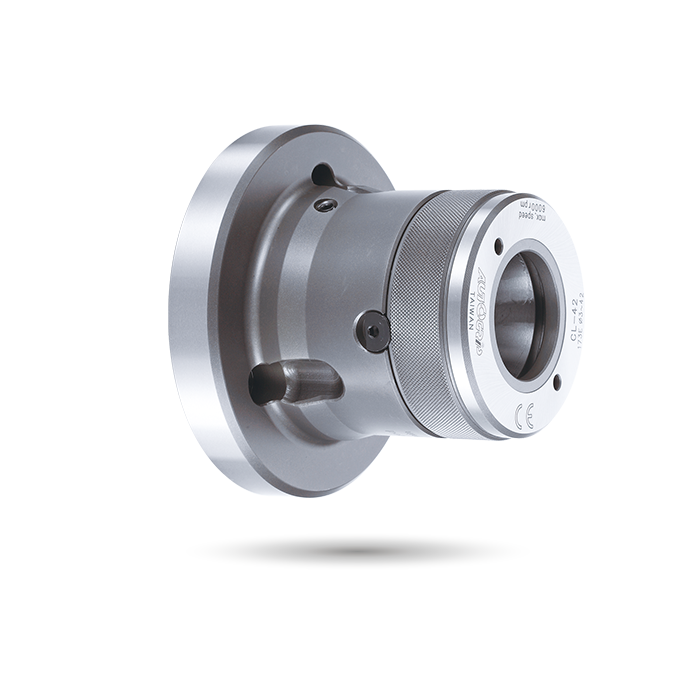

CL-A DIN6343

DIN6343 CB/CB-A

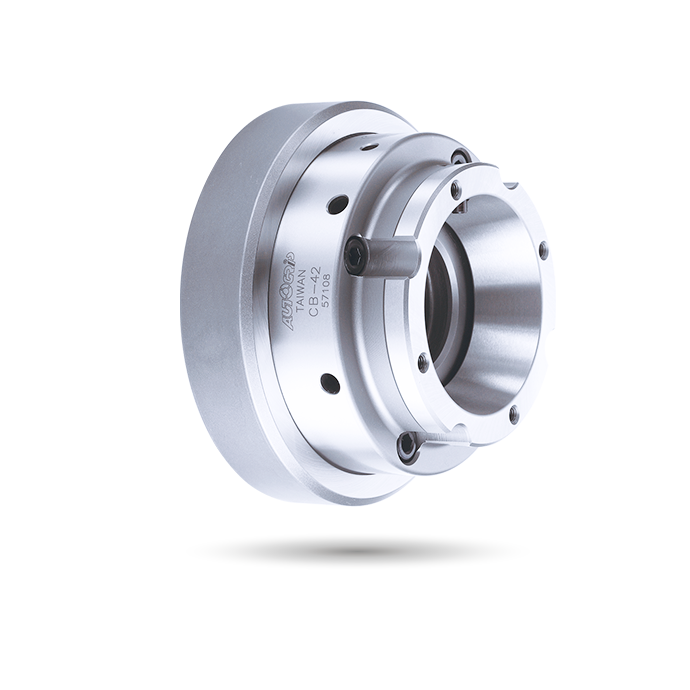

CB/CB-A CBE/CBE-A

CBE/CBE-A CBD/CBD-A

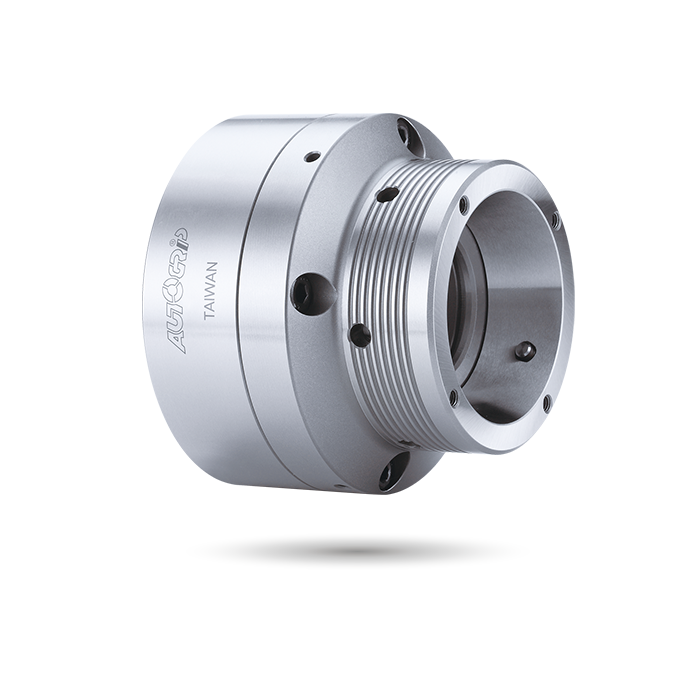

CBD/CBD-A SCB

SCB RG

RG