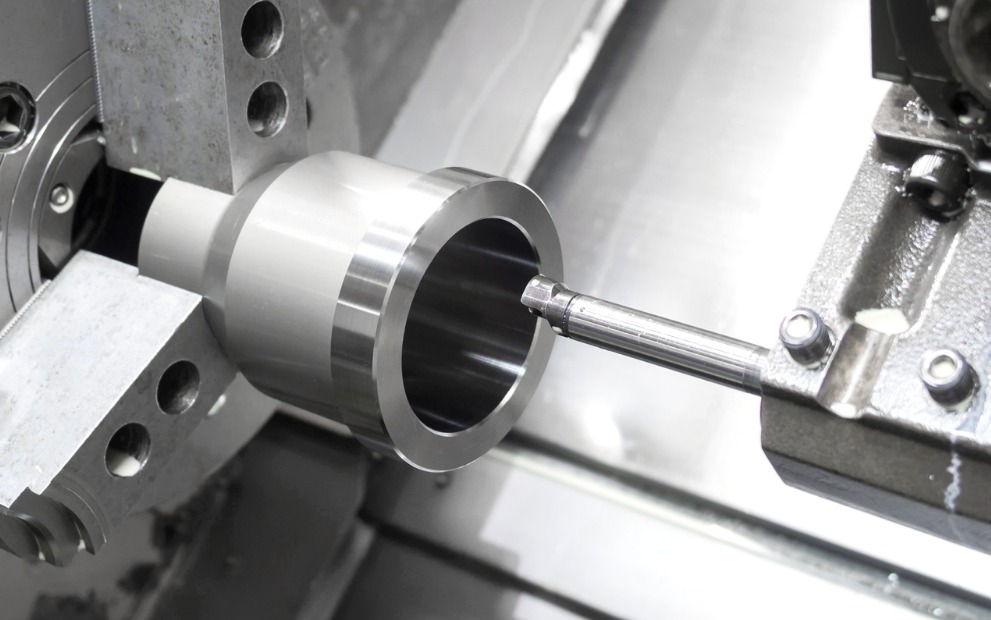

Precision Clamping Solutions for Enhanced Turning Center Performance #

In the realm of turning operations, the stability of workpiece clamping directly influences machining accuracy and operational efficiency. Chucks serve as indispensable clamping tools on turning centers, securing the workpiece to ensure both stability and high-quality turning results.

The Importance of Chucks in Turning Centers #

Stable clamping is a cornerstone of precision turning. Chucks are essential for several reasons:

-

High-Precision Machining

Chucks deliver robust and stable clamping force, minimizing runout and maintaining concentricity and surface finish. This is particularly vital for the precision turning of critical components. -

Clamping Stability and Safety

By firmly holding the workpiece during high-speed rotation, chucks prevent slippage or ejection, reducing the risk of machine damage or scrap and enhancing operational safety. -

Versatility for Various Workpieces

With options such as power chucks, collet chucks, and special-purpose chucks, users can select the most suitable type based on the size, shape, and material of the workpiece, accommodating both standard and specialized applications. -

Reduced Changeover Time

Quick-change and automated clamping systems streamline workpiece loading and unloading, minimizing downtime and increasing production efficiency—particularly advantageous for mass production and automation. -

Enhanced Machine Rigidity and Durability

High-quality chucks offer superior rigidity and wear resistance, supporting heavy-duty machining and extending the service life of the machine.

Chucks are thus critical components in turning centers, ensuring not only clamping stability and machining precision but also contributing to productivity and safety. Selecting the right chuck makes turning operations more efficient, reliable, and adaptable.

Advantages of Pairing AUTOGRIP Chucks with Turning Centers #

Turning centers are high-performance CNC machines widely used in industries such as automotive, aerospace, and precision machinery. Choosing AUTOGRIP chucks can significantly elevate machining efficiency and accuracy. Key benefits include:

- Stable Clamping Force & High Precision: AUTOGRIP chucks maintain workpiece stability even at high speeds, reducing runout and machining errors.

- Rigid Design: Minimizes vibration, extends tool life, and lowers processing costs.

- Comprehensive Range: From power chucks and rubber collet chucks to special fixtures, AUTOGRIP offers solutions for irregular and precision parts.

- Reliable Quality: Precise engineering ensures consistent performance, making AUTOGRIP chucks valuable tools for optimizing production and competitiveness.

Product Categories for Turning Centers #

Custom Solutions and Expertise #

With over 35 years of experience, AUTOGRIP offers high-precision chucks, custom solutions, and ODM services to meet diverse machining requirements. For more information or tailored solutions, contact us.

Stay informed about the latest developments and product updates by subscribing to the AUTOGRIP mailing list.

Power Chucks

Power Chucks Special Purpose Power Chucks

Special Purpose Power Chucks Collet Chucks

Collet Chucks Rotary Cylinders

Rotary Cylinders Steady Rest

Steady Rest