The Critical Role of Chucks in Modern Machining Centers #

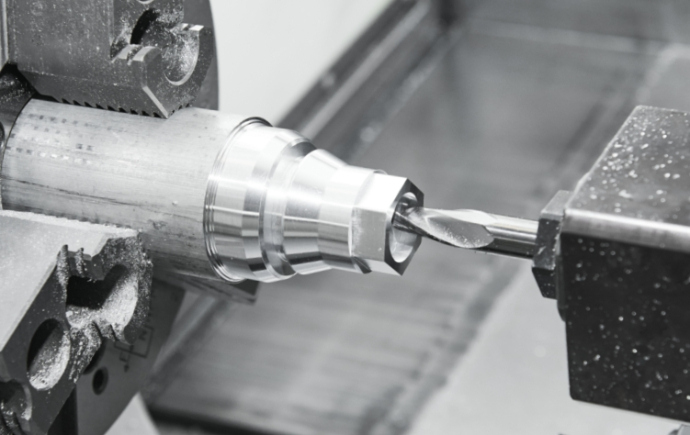

Chucks are indispensable components in machining centers, supporting multi-step, multi-face, and high-precision operations. Their primary function is to secure workpieces, but their influence extends to ensuring machining stability, accuracy, and operational efficiency.

Why Chucks Matter in Machining Centers #

Chucks are foundational to achieving reliable and precise machining. Their benefits include:

-

Stable Clamping for High-Precision Work

Machining centers require unwavering precision. Chucks deliver consistent and balanced clamping force, minimizing vibration or displacement during high-speed cutting—crucial for producing precision parts. -

Enhanced Efficiency and Reduced Setup Time

Certain chuck types, such as rubber collet chucks, enable rapid workpiece loading and unloading. This dramatically reduces changeover time, boosting production speed—especially valuable in multi-step and high-volume manufacturing environments. -

Adaptability for Complex and Multi-Face Machining

Chucks offer flexible clamping solutions for irregular or variable-sized workpieces. Whether used in vertical (VMC) or horizontal (HMC) setups, they support multi-angle clamping, facilitating seamless multi-face machining processes. -

Improved Safety During Production

Reliable clamping systems help prevent workpiece ejection and reduce the risk of injuries. Stable chuck setups also protect machines from vibration-induced damage and extend equipment lifespan. -

Support for Automation and Reduced Labor Costs

Advanced machining centers can integrate chucks with automation systems, enabling unmanned operations and automatic loading/unloading. This reduces labor requirements and enhances consistency and efficiency. -

Versatile Clamping Options

From stationary to power and specialized chucks, machining centers can select the optimal clamping solution based on workpiece size, shape, and material, ensuring the best performance for any application.

Chucks are more than just holding devices—they are key to precision, productivity, safety, and flexibility in both low-volume precision and high-volume automated manufacturing.

Advantages of AUTOGRIP Chucks in Machining Centers #

In precision machining, the quality of the clamping system directly impacts output. AUTOGRIP chucks are widely adopted in milling machines and machining centers for their robust clamping force and precision. Their high-rigidity design minimizes vibration, extends tool life, and is ideal for demanding, high-precision cutting tasks.

Quick-change features further enhance efficiency by reducing downtime, meeting the demands of modern manufacturing. AUTOGRIP offers a broad range of specifications and custom solutions, ensuring compatibility with diverse equipment and machining conditions. Whether for heavy-duty cutting or intricate detail work, AUTOGRIP chucks provide stable, reliable clamping that helps businesses improve quality and productivity—making them a cornerstone in precision machining industries.

Explore Our Chuck Solutions #

More Chuck Options #

- Power Chucks

- Special Purpose Power Chucks

- Collet Chucks

- Stationary Chucks

- Power Centering Vise

- Manual Chucks

- Synchronous Clamps

- Rotary Cylinders

- Rotary Joints

- Pneumatic Rotary Chucks

- Facing Heads

- Rotary Valves

- Tool Holder

- Lathe Chuck Parts and Accessories

Ready to Enhance Your Machining Efficiency? #

With over 35 years of expertise, AUTOGRIP offers high-precision chucks, custom solutions, and ODM services for advanced manufacturing needs. Contact us today to discuss how our clamping solutions can elevate your machining performance.